Our Unique Printing Process

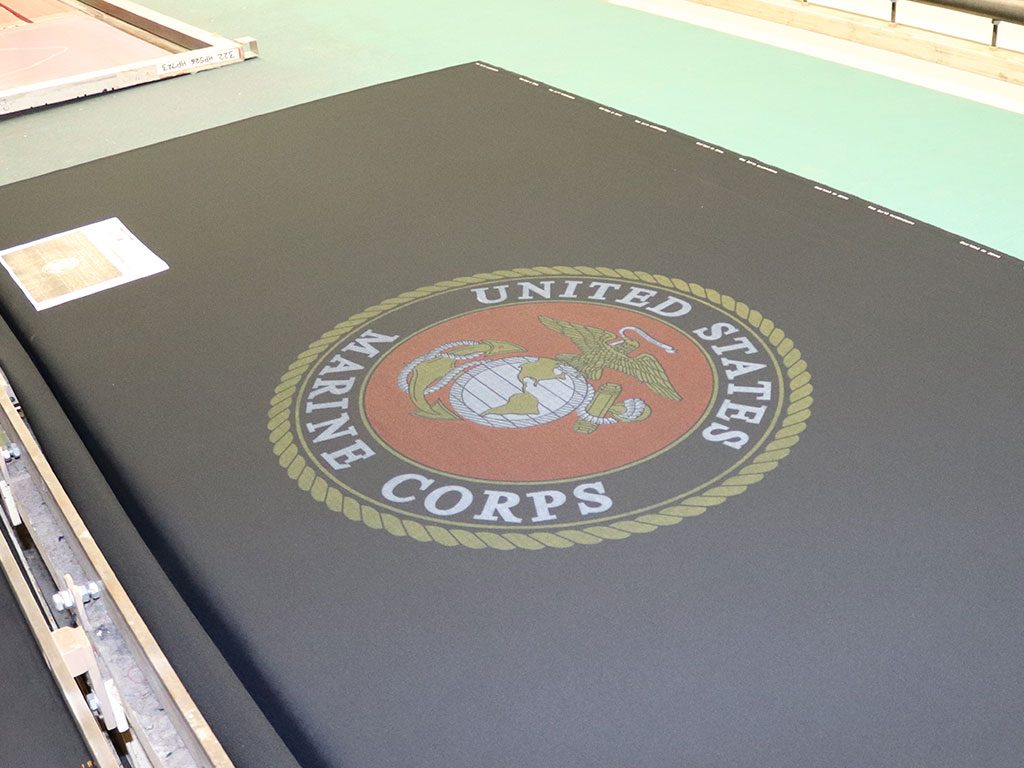

The print is transferred to the cloth through dischargeable dye, which destroys the base colour of the cloth and replaces with the colour of the print. The result is a print that becomes a part of the cloth, ensuring a completely smooth surface with no resistance to the ball. We are able to print on Smart and Elite-Pro pool table cloths.

There are many benefits to using this technique over alternative screen-printed cloths on the market. The print area is very durable, lasts as long as the cloth is in use, does not scratch or wear off and there is no resistance to the ball when in play. There are digital printed cloths on the market, however they do not stay smart for long. Digital prints start with a white base cloth and are printed on the surface. The print can also come away when scratched and worn.

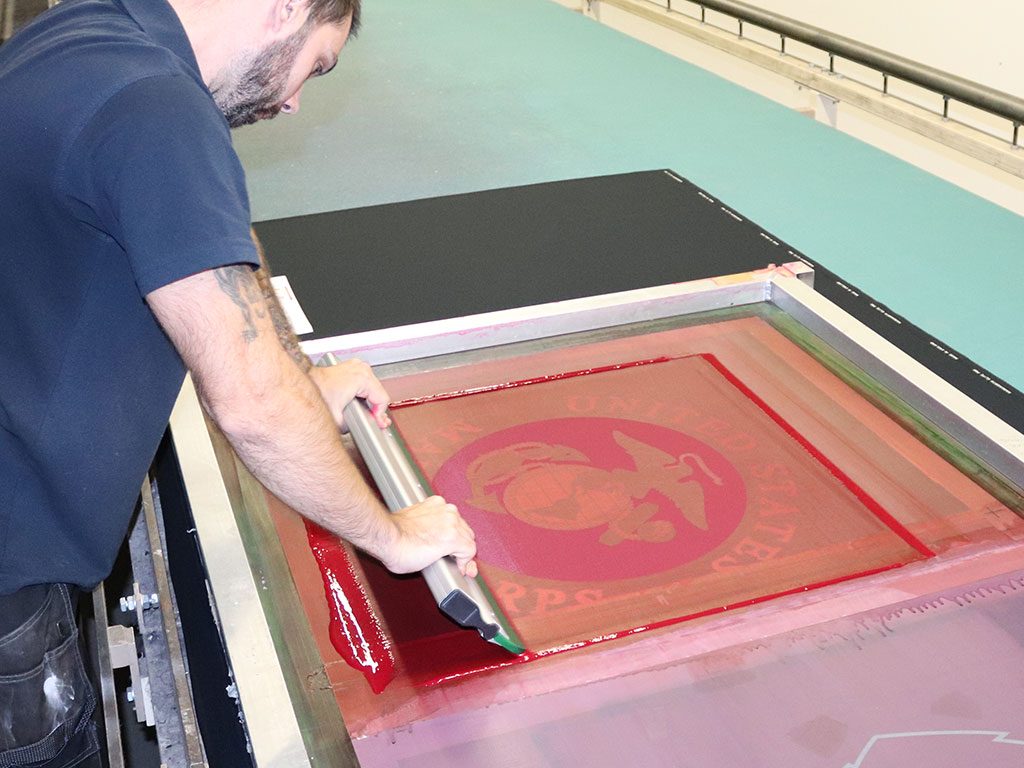

The process begins with the selection of the logo or design that will be printed onto the cloth. If we have your chosen design within our screen library then we will not need to create new screens. If it is a new design, we then go through the following process:

Contact us today

to discuss your own custom printed pool cloth.